The Products You’re Looking For

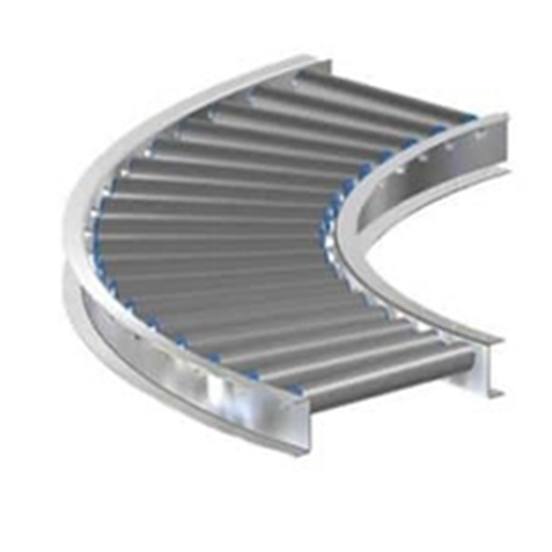

Light Duty - Curve

Available with 30° to 90° turns, available in manual or self-powered options, ideal for diverse warehouse applications.

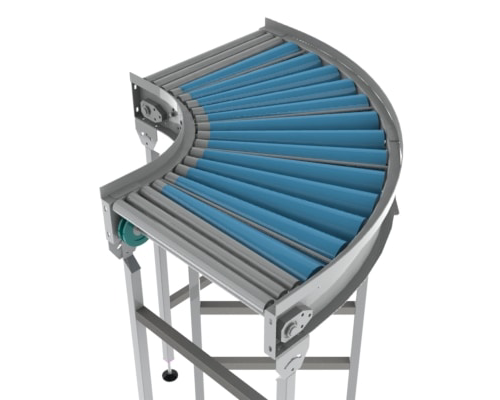

Medium Duty - Curve

Available in 30° to 90° turns and made from stainless steel, PVC, UMHW, aluminum, or mild steel, can handle loads up to 600 lbs.

Ball-N-Sokit Roller

Offers a maintenance-free alternative to ball bearing rollers, available in multiple axle sizes and roller materials like stainless steel, PVC, UHMW, or mild steel.

Roach Spring Loaded

These spring-loaded parts enhance conveyor rollers by providing increased lifting capacity with minimal effort through tensioned springs.

Belt Driven Live Roller

Specifically and powerfully designed for effectively handling hard-to-convey items like bundles, drums, pails, and other heavy or awkward materials.

Plastic Conveyor

Best for highly corrosive environments, features a polypropylene welded frame, belt & sprockets, with 316 SS shafts & hardware.