Stainless Steel Conveyor Rollers for Hygienic Environments

Built to withstand harsh environments, our stainless conveyor rollers offer exceptional durability and corrosion resistance. Ideal for food processing, pharmaceuticals, and chemical industries.

Related: Explore Food Grade Conveyor Rollers for similar hygienic solutions.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

PVC Conveyor Rollers for Moisture-Resistant Applications

Lightweight and non-corrosive, our PVC rollers are ideal for clean and quiet operations in food packaging, electronics, and pharmaceutical settings.

Related: Also consider our Plastic Conveyor Rollers for cost-effective alternatives.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

Gravity Conveyor Rollers for Manual Handling

Our gravity rollers provide reliable, low-cost material transport powered by gravity alone. Designed for simplicity and ease of use, these rollers are ideal for assembly lines, warehouses, and shipping stations looking for manual flow solutions.

Related: Need automated options? Check out our Powered Roller Conveyors.

Key Features:

- Non-powered, low-maintenance operation

- Light to medium load handling

- Available in aluminum, steel, PVC, or stainless steel

- Customizable length, pitch, and mounting styles

Conveyor Belt Rollers for Smooth Belt Tracking

Engineered for durability and precision, our belt rollers ensure optimal alignment and long-term belt health in demanding environments.

Related: For bulk loads, explore Heavy Duty Conveyor Rollers.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

Food Grade Conveyor Rollers for Sanitary Compliance

Made from FDA-approved materials, our rollers meet the strict hygiene standards of food handling and cleanroom facilities.

Related: Pair with Stainless Conveyor Rollers for a full sanitary solution.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

Nylon Conveyor Rollers for Lightweight, Low-Noise Handling

Designed for sensitive goods and clean environments, nylon rollers offer quiet operation and chemical resistance across various sectors.

Related: Also view Plastic Conveyor Rollers for similar lightweight use.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

Plastic Conveyor Rollers for Lightweight Transport

Durable and economical, plastic rollers are ideal for medium-speed lines in packaging, e-commerce, and assembly applications.

Related: Compare with PVC Conveyor Rollers for moisture-prone areas.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

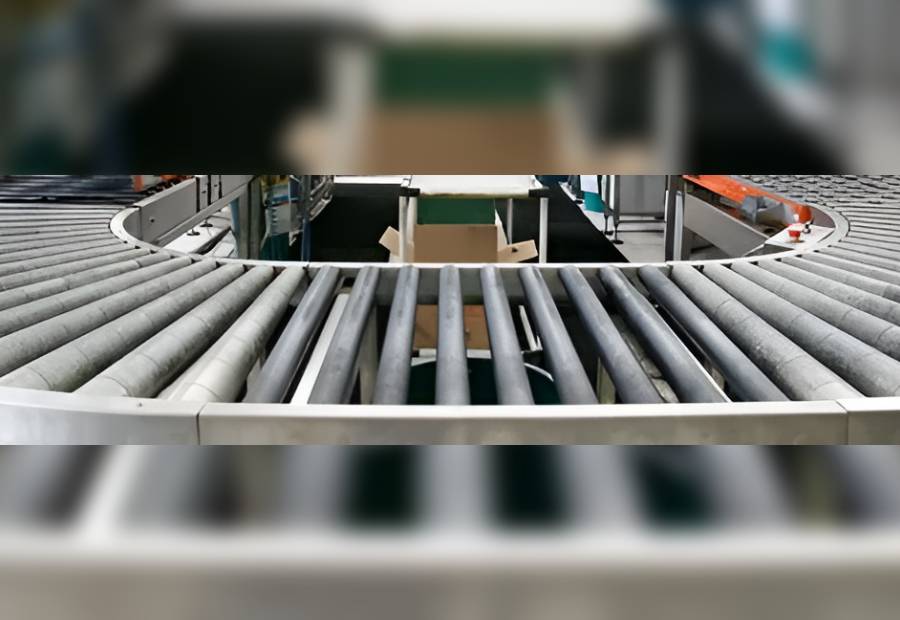

Tapered Conveyor Rollers for Curve Handling

Guide packages around corners without misalignment using tapered rollers engineered for flow precision and smooth transitions.

Related: Integrate with Gravity Rollers for passive curved systems.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

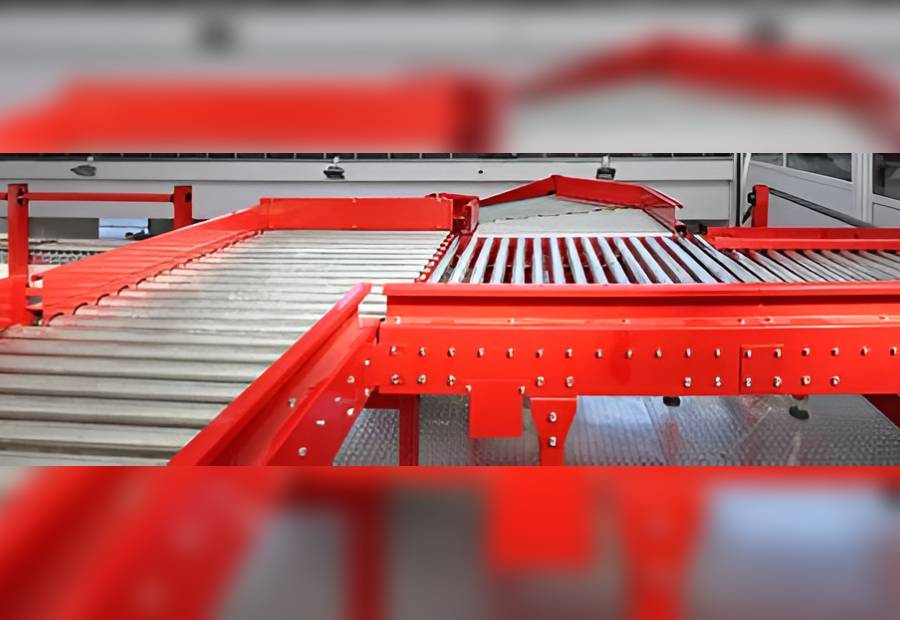

Heavy Duty Conveyor Rollers for High-Load Performance

Built for strength and longevity, these rollers support heavy loads in mining, automotive, and rugged industrial applications.

Related: Use with Belt Rollers for secure pallet transport.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems

Industrial Rollers

Versatile and robust, our industrial rollers are designed to meet the diverse needs of manufacturing, logistics, and warehousing operations. Whether transporting pallets, cartons, or irregularly shaped goods, these rollers deliver smooth, consistent movement across a wide range of applications.

At Conveyor Systems & Engineering, Inc., we offer industrial rollers in various materials, finishes, and sizes, customized to your workflow requirements. With durability, precision, and performance at the core, our industrial rollers help maximize uptime and operational efficiency in any industrial setting.

Poly-V Conveyor Rollers for High-Speed Lines

With quiet operation and synchronized movement, Poly-V rollers are perfect for dynamic sortation and packaging zones.

Related: Combine with Motorized Rollers for fully automated control.

Key Features:

- Custom-engineered for optimized flow

- Reliable, tested, and maintenance-friendly design

- Available in various materials and load capacities

- Integrates with existing conveyor systems